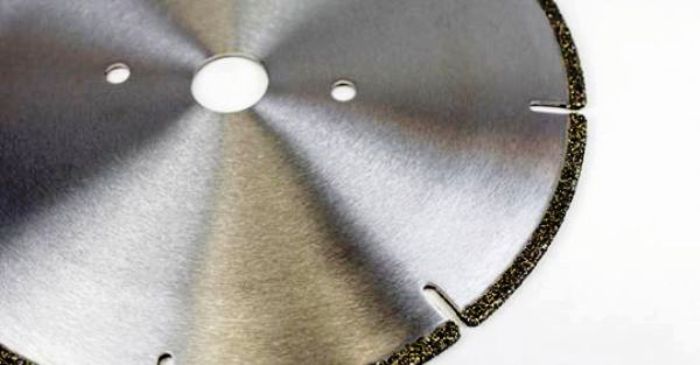

Etched glass panels are great on standard tempered glass doors as well as hurricane impact glass inserts. This door option works great for those who are living by the coast or near the bay. In fact, many homeowners decided to convert their front doors into hurricane impact glass doors for added protection. Now, the major concern would be how to make this conversion without compromising the tropical and casual feel that living in the area provides. Well, obviously, the simple answer is by adding an etched design using diamond cutting tools.

The most common design idea to complement the tropical lifestyle is the leaf pattern etched on your glass panels. If privacy is a primary concern for you, then the glass etching can be done with diamond cutting tools on the outside panel. This will allow the pattern to be displayed on the street view without compromising your privacy. This technique is known as glue chip wherein the light is allowed to enter through the glass but its texture still gives privacy to the interior.

In order to achieve the desired pattern or design, glass etching involves a layered process where a definite method is done to remove the template for etched panels. A very sharp instrument is needed, which is why this work is usually conducted with diamond cutting tools. This results in the correct sequencing of shadows and layers of glass etching. You may opt for a simple or more intricate design to be etched on your impact glass door. You may even combine different designs together to create a new and unique pattern. Your choices are almost unlimited and your imagination is the only limit. Make sure you consult with a qualified service provider with any of your design ideas or even without it. The craftsman will discuss and put it all together for you, giving you the best possible result for a beautiful and eye-catching glass door by the bay.

RSS Feed

RSS Feed