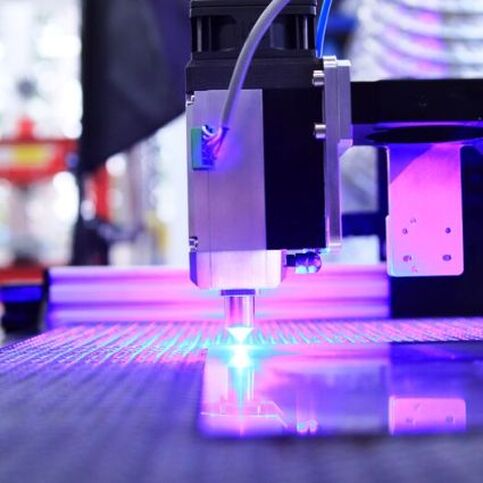

Moreover, the improved efficiencies of fabricating downstream a laser makes it suitable for cutting pipes, tubes, and other structural materials. A host of laser cutting machines can provide the requirements for high accuracy and 6-axis laser technology as well as for handling thicker, longer and heavier materials. Plus, the invention of direct diode laser technology also facilitates easier and faster cutting speeds for laser cutting.

Precision laser cutting decreases the amount of time needed by downstream processes like welding, bending, and assembly. Thanks to the 3D laser cutting head that allows for complex and intricate geometries from mitered and beveled end cuts. It can cut any desired angle for welding preparation while achieving the highest precision for easier fit-up assemblies. Moreover, laser cutting effectively addresses the common inconsistencies with structural materials particularly when it comes to their shapes. These include twisting, bowing, and misshaping that can compromise the integrity of the structure.

By having complete control in cutting the materials and making very precise tubes and pipes, lasers can help minimized those inconsistencies. This is due to the characteristics of laser beams which can create a minimized heat-affected section on the material and its fast cutting speeds. This ultimately leads to lower heat and time required to cut the material but producing high-quality cuts and edges.

RSS Feed

RSS Feed